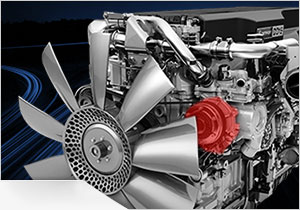

Variable Speed Water Pump: Designed for Efficiency

The first major feature of the new DD15 engine I wanted to zoom in on is the Variable Speed Water Pump. As I mentioned in my last DD15 post <link to blog post>, this water pump is raising the bar with its cutting-edge design and helping the DD15 reach new levels of performance.

The first major feature of the new DD15 engine I wanted to zoom in on is the Variable Speed Water Pump. As I mentioned in my last DD15 post <link to blog post>, this water pump is raising the bar with its cutting-edge design and helping the DD15 reach new levels of performance.

First and foremost, the Variable Speed Water Pump reduces parasitic power losses, thereby increasing fuel economy. It features a viscous clutch between the pulley and impeller drive, allowing the engine to command reduced impeller speed when other engine conditions allow it. This design is advanced compared to traditional pumps where pump speed is a fixed function of engine speed.

Another innovative feature of the pump design is an impeller speed sensor that is coupled to the engine control module. This means is that the engine control module is constantly monitoring and adjusting impeller speed through a closed-loop system. This system also allows the engine control module to react with full impeller speed in case of a broken circuit or other electrical fault.

The Variable Speed Water Pump is just one of the factors that makes the Detroit DD15 the most fuel-efficient, low maintenance heavy-duty engine on the road today. To make good news even better, this water pump can also be found on the DD13 engine.

In the coming months, we’ll be using this blog as an opportunity to provide you with in-depth information on many aspects of the DD15 and DD13 engines. We also want to start a conversation with you, so feel free to ask questions and make comments. Check back here next week when we’ll be discussing the new Proprietary Asymmetric Turbocharger.